Warehouse Optimisation in AR: Transforming Efficiency and Productivity

Author: Spark Team

Author: Spark Team

Warehouse Optimisation in AR: Transforming Efficiency and Productivity

Introduction to Warehouse Optimisation in AR

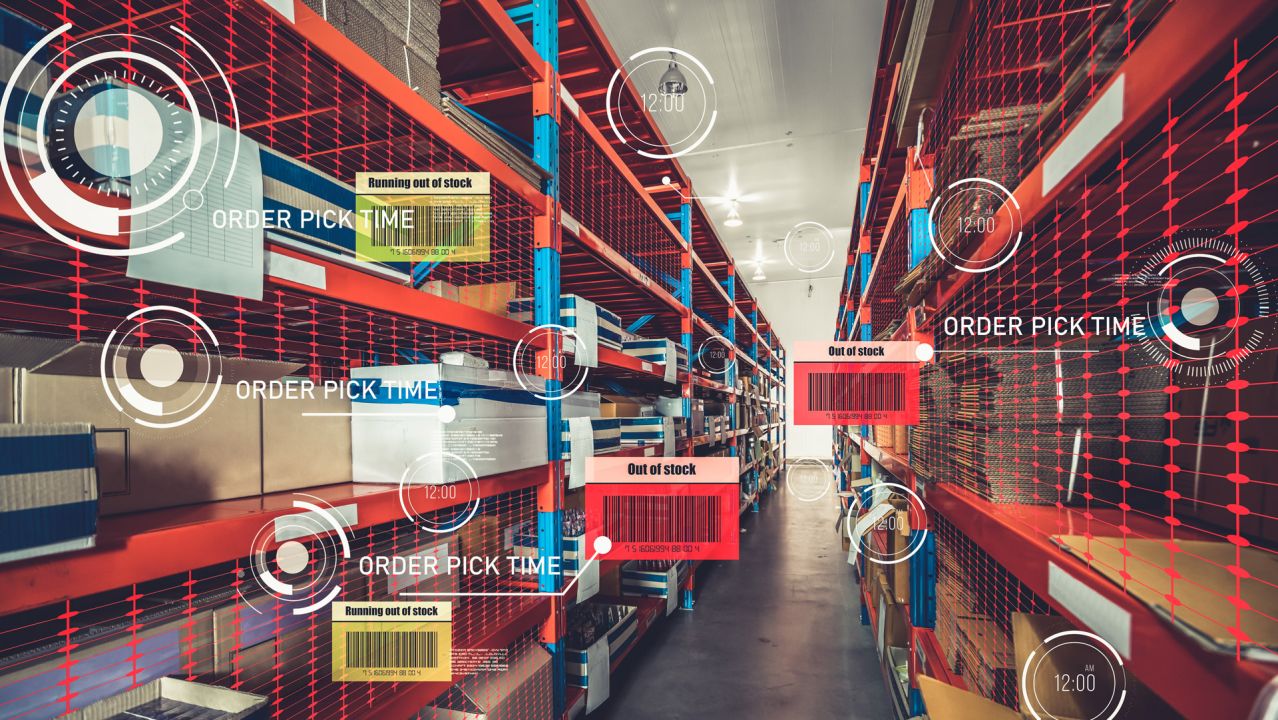

In the fast-paced world of logistics and supply chain management, optimising warehouse operations is essential for enhancing efficiency and productivity. Augmented Reality (AR) provides an innovative solution for visualising and managing warehouse layouts, inventory, and workflows, enabling organisations to streamline their operations. Spark Emerging Technologies specialises in developing AR solutions that enhance warehouse optimisation, helping businesses achieve operational excellence.

Benefits of Warehouse Optimisation in AR

Implementing AR for warehouse optimisation offers numerous advantages that improve operational performance:

Enhanced Visualisation: AR allows warehouse staff to visualise inventory locations and workflows in real-time, making it easier to navigate the warehouse efficiently.

Improved Picking Accuracy: By overlaying information on physical environments, AR can guide workers to the exact locations of items, reducing errors in order fulfilment.

Streamlined Processes: AR can simulate workflows and identify bottlenecks, helping organisations optimise processes for increased efficiency.

Real-Time Data Integration: AR can display live data, such as stock levels and inventory movement, enabling informed decision-making and proactive inventory management.

Training and Familiarisation: AR can be used to train employees on warehouse systems and layouts, ensuring they are well-versed in operations before engaging in real-world tasks.

Real-World Applications of Warehouse Optimisation in AR

Inventory Management: AR can assist in visualising inventory levels and locations, enabling staff to manage stock more effectively and reduce overstock or stockouts.

Order Picking: Warehouse staff can use AR to receive real-time picking instructions, guiding them through the most efficient routes to collect items for orders.

Layout Planning: AR can help organisations visualise different warehouse layouts and assess their impact on efficiency, allowing for data-driven decisions on space utilisation.

Quality Control: AR can facilitate quality checks by overlaying inspection criteria on items as they are processed, ensuring compliance with standards.

Maintenance Management: AR can provide maintenance staff with visual instructions and checklists for equipment, helping to streamline repair processes and minimise downtime.

How Spark Emerging Technologies is Leading AR Solutions for Warehouse Optimisation

At Spark Emerging Technologies, we specialise in developing AR solutions that enhance warehouse optimisation across various industries. Our interactive applications provide logistics teams with the tools they need to visualise and manage their operations effectively. By collaborating with organisations, we create tailored AR experiences that address specific warehouse management challenges and improve overall efficiency.

Addressing Key Challenges with AR for Warehouse Optimisation

User-Friendly Interfaces: Our AR applications are designed with intuitive navigation and controls, ensuring that warehouse personnel can easily engage with the optimisation features.

Integration with Existing Systems: We ensure our AR solutions seamlessly integrate with existing warehouse management systems, providing a comprehensive view of operations.

Data Privacy and Security: Protecting sensitive inventory data is essential; we implement robust security measures to safeguard information collected during AR interactions.

Scalability Across Various Operations: Our AR solutions are adaptable, allowing for deployment across different sectors and warehouse configurations.

Case Study: AR for Warehouse Inventory Management

A leading e-commerce retailer partnered with Spark Emerging Technologies to implement AR solutions for optimising their warehouse operations. The AR application allowed employees to visualise inventory locations and receive real-time picking instructions. As a result, the company reported a 30% increase in order fulfilment accuracy and a significant reduction in picking time.

The Role of AR in Advancing Warehouse Optimisation

Warehouse optimisation in AR is transforming how organisations approach logistics and supply chain management. By providing immersive experiences that enhance visualisation and interaction, AR fosters a proactive approach to warehouse operations and decision-making. This innovative method not only improves operational efficiency but also empowers teams to take control of their warehouse processes.

Future of Warehouse Optimisation in AR

As AR technology continues to advance, the potential for warehouse optimisation applications will expand significantly. Spark Emerging Technologies is committed to enhancing our AR solutions, anticipating more sophisticated applications that empower organisations to optimise their warehouse management strategies. The future promises increasingly interactive and data-rich AR experiences that will play a crucial role in improving warehouse operations.

Conclusion

Warehouse optimisation in AR offers transformative solutions for enhancing efficiency and productivity in logistics. Spark Emerging Technologies provides cutting-edge AR applications that enable organisations to visualise and manage their warehouse operations effectively, fostering a culture of operational excellence. Discover how our AR solutions can enhance your warehouse management processes—contact Spark Emerging Technologies for a demo today.

Contact Us:

Interested in optimising your warehouse operations with AR? Contact Spark Emerging Technologies to schedule a consultation and learn how our solutions can benefit your organisation.

© 2026 All Rights Reserved | Company Reg No. 05327622 | Spark Emerging Technologies Limited