VR SOP Training for Kitchen & Bathroom Manufacturing (Solid Surface)

Author: Spark Team

Author: Spark Team

VR SOP Training for Kitchen & Bathroom Manufacturing (Solid Surface)

Make templating, fabrication and installation simple and repeatable

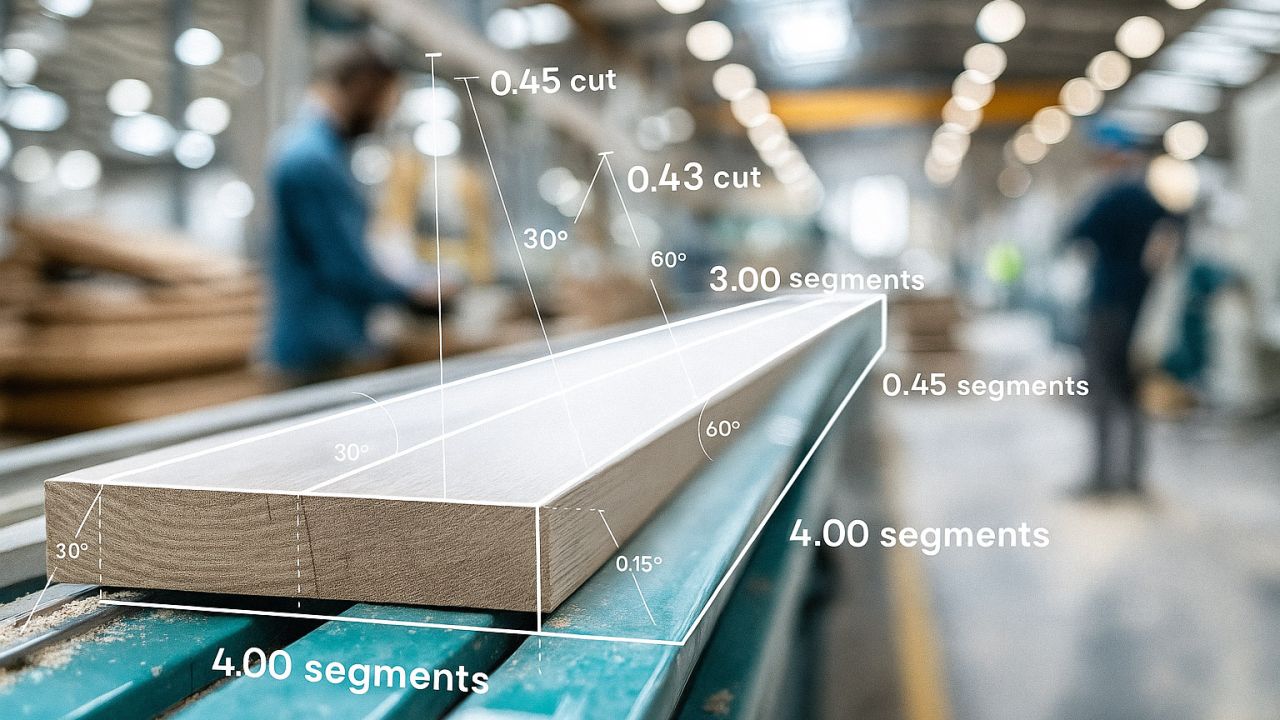

Solid-surface and stone work demands precise templates, safe handling and clean finishing. Spark designs bespoke VR training that matches your templating, CNC cutting, edge profiling, seaming and site installation steps—so teams learn the right order and safety habits.

Typical challenges

- Template to cut errors: wrong allowances, sink/hob offsets and datum choices.

- Seam quality: colour match, adhesive ratio, clamping pressure and cure times.

- Dust & silica risk: extraction, wet-cutting and PPE compliance.

- Install damage: lifting technique, transport protection and site checklists.

Our bespoke build approach

- Capture your SOPs: template rules, CNC programs, seaming and finishing standards.

- Build scenarios: nesting, cut/edge profiles, sink cut-outs, seam practice and site fit.

- Coach in VR: step prompts that match your forms and QA gates.

- Assess: right-first-time rates, rework causes and safety behaviours.

Benefits

- Cleaner seams and better site fit the first time.

- Lower breakage and install damage.

- Safer dust control and handling.

Why Spark

We train your exact methods and finish specs—so practice matches the job.

Let’s design a solid-surface VR trainer for your team. Contact Spark.

© 2026 All Rights Reserved | Company Reg No. 05327622 | Spark Emerging Technologies Limited