VR SOP Training for Flexible Packaging: Film Extrusion & Lamination

Author: Spark Team

Author: Spark Team

VR SOP Training for Flexible Packaging: Film Extrusion & Lamination

Make recipes, threading and defect control easy to learn and repeat

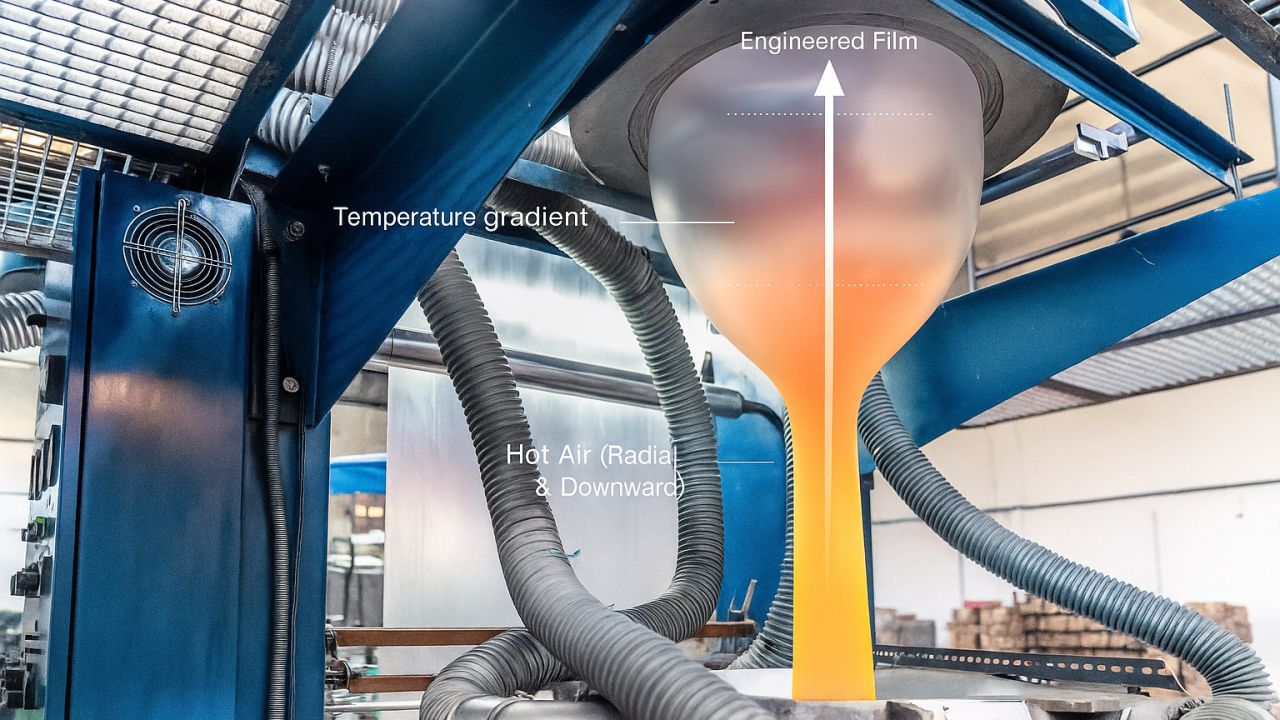

Film and laminate lines are sensitive to small changes. Wrong temperatures, tension or adhesives mean scrap. Spark designs bespoke VR training that mirrors your extruders, dies, winders, coaters, laminators and slitters—so teams gain confidence before live production.

Typical issues

- Recipe and temperature errors that cause gels, haze or poor bond strength.

- Threading and tension mistakes that lead to wrinkles and breaks.

- Adhesive/coating problems (mix ratios, coat weight, cure).

- Safety risks around hot surfaces, nip points and solvents.

Our simple build process

- Capture your SOPs: start-up/shutdown, threading, recipe changes and QC tests.

- Create scenarios: die change, recipe swap, bond failure recovery, slitter setups.

- Coach in VR: prompts that match your screens and checklists.

- Assess & improve: right-first-time, defect trends, re-training needs.

Benefits

- Higher yield and fewer off-spec rolls.

- Quicker changeovers with less risk.

- Clear competence proof for customers and audits.

Why Spark

We build to your lines, chemistries and targets—no generic training.

Explore a VR trainer for films and laminates. Contact Spark.

© 2026 All Rights Reserved | Company Reg No. 05327622 | Spark Emerging Technologies Limited