VR SOP Training for Electric Drivetrain & Inverter Manufacturing

Author: Spark Team

Author: Spark Team

VR SOP Training for Electric Drivetrain & Inverter Manufacturing

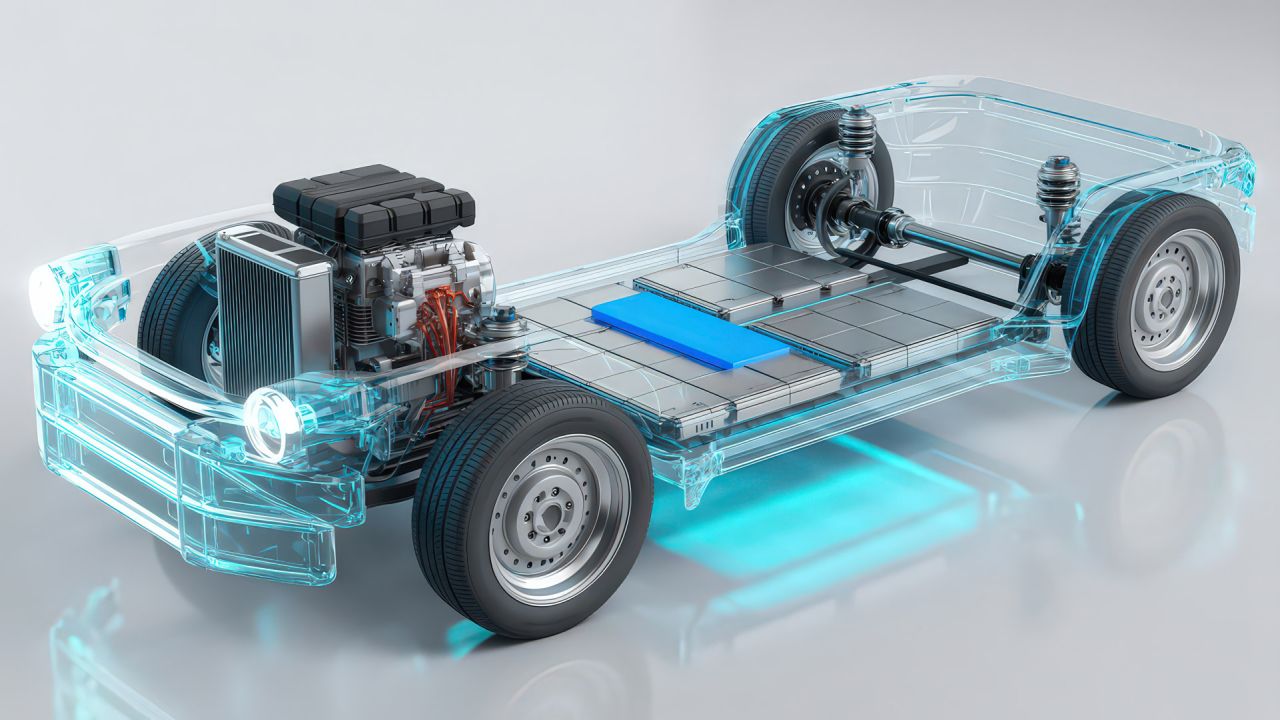

Custom VR to standardise HV safety, precision assembly and test sequences

EV powertrain production blends precision mechanical builds with high-voltage safety and complex end-of-line tests. Spark builds bespoke VR SOP training that mirrors your rotor/stator assembly, gearbox integration, inverter PCB/power module builds and HV test bays—so teams rehearse critical steps without risking people or equipment.

Pain points we address

- HV safety & isolation: lockout/tryout, proving dead, PPE, safe test-bay protocols.

- Precision assembly: bearing preload, tolerance stacks, torque/angle, seal integrity.

- Power electronics: thermal interface materials, cleaning/contamination control, ESD.

- EOL testing: hipot, insulation resistance, functional drive cycles and NVH checks.

- Variant complexity: platform options, firmware versions, connector families and cooling circuits.

Our bespoke build method

- SOP & CTQ capture: golden build sequence, inspection hold points and HV permits.

- Digital twin stations: wind/insert, press fits, sealant stations, PCB assembly and HV bays.

- AI avatar coaching: prompts for HV boundaries, torque maps, TIM application and ESD checks.

- Assessment & analytics: right-first-time, leak/insulation failures, cycle time and defect heatmaps.

- Integration: LMS/QMS/MES links, multilingual modules, role paths for ops, test and QA.

Commercial outcomes

- Safer HV operations and fewer EOL test failures.

- Reduced rework and warranty risk via disciplined builds.

- Faster ramp-up on new platforms and variants.

- Audit-ready competence for OEM and regulatory requirements.

Why Spark

Your simulator reflects your stations, limits and quality controls—no generic modules—ensuring skills transfer straight to the cell and test bay.

Start a bespoke VR SOP programme for EV drivetrains and inverters. Contact Spark.

© 2026 All Rights Reserved | Company Reg No. 05327622 | Spark Emerging Technologies Limited