VR SOP Training for Battery Gigafactories: Cell Assembly & Formation

Author: Spark Team

Author: Spark Team

VR SOP Training for Battery Gigafactories: Cell Assembly & Formation

De-risk scale-up, standardise changeovers, and protect yield with bespoke VR

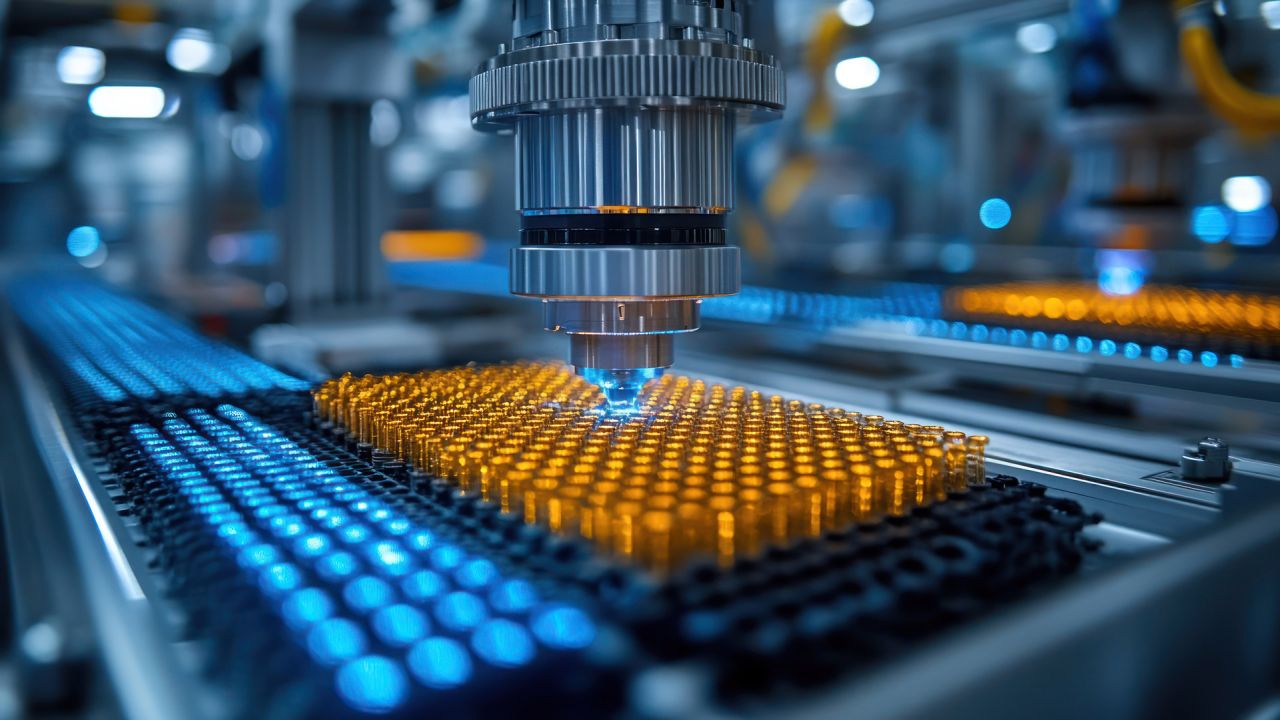

High-volume Li-ion cell manufacturing demands precision across dry rooms, electrode coating, calendaring, slitting, stacking/winding, electrolyte filling, formation, and ageing. Spark delivers bespoke VR SOP training that mirrors your exact production line, tooling, parameters, and safety controls—so teams can practise critical steps before live production, protecting yield and throughput.

Gigafactory pain points

- Dry room discipline: ingress/egress, moisture control, and material staging.

- Changeovers: recipe swaps, web threading, alignment, and line clearance.

- Hazardous chemistries: solvent handling, electrolyte filling, and thermal runaway response.

- Quality drift: coating uniformity, burr control, particle contamination, and pouch/can integrity.

- Ramp-up & training: rapid hiring cycles and skills standardisation across shifts.

Our custom VR build process

- SOP & equipment capture: map OEM line configs, interlocks, and parameter windows.

- Scenario design: start-up/shut-down, threading, burr inspection, electrolyte dosing, formation safety.

- AI avatar guidance: step prompts, critical limit alerts, and quality hold-point checks.

- Assessment & analytics: cycle time, right-first-time, deviation patterns, and retraining cues.

- Integration: LMS connectivity, multilingual packs, role-specific modules (operators, techs, QA).

Commercial outcomes

- Faster line ramp-up with fewer yield-killing errors.

- Consistent execution of complex changeovers across crews.

- Improved EHS performance around solvents and high-energy systems.

- Audit-ready competence records for OEM and customer assurance.

Why Spark

We tailor the simulator to your line configuration, SOPs, and quality controls—supporting stable ramp-up and sustainable OEE gains.

Plan a bespoke gigafactory VR SOP programme. Contact Spark.

© 2026 All Rights Reserved | Company Reg No. 05327622 | Spark Emerging Technologies Limited