VR Hazard Awareness for Luxury Glass & Crystal Manufacturing

Author: Spark Team

Author: Spark Team

VR Hazard Awareness for Luxury Glass & Crystal Manufacturing

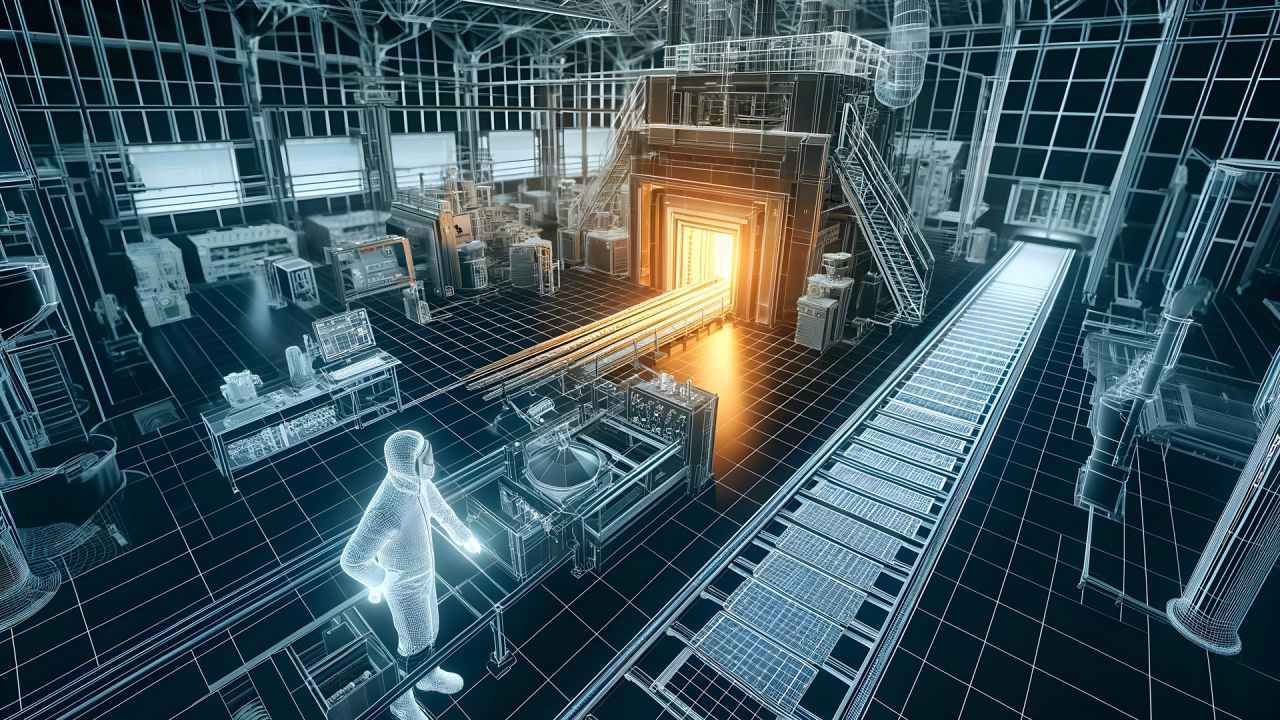

Luxury glass and crystal production is a craft that blends heritage artistry with high-risk manufacturing. From molten furnaces to delicate finishing, workers face hazardous conditions where mistakes can be costly and dangerous. With regulators enforcing tighter HSE and SOP requirements, luxury glassmakers must embrace new digital solutions that protect staff, ensure compliance, and safeguard product quality.

The Legislative Landscape

Updated EU workplace safety directives and national HSE frameworks now require manufacturers to prove training in high-temperature operations, chemical handling, and ergonomic safety. Compliance audits demand more than documented policies; regulators want evidence of how training translates into safe behaviour in real-world conditions.

The Unique Hazards of Glassmaking

Molten furnaces, heavy lifting, and exposure to dust and chemicals make glass and crystal production one of the more hazardous luxury industries. Traditional training often fails to replicate these risks, leaving workers unprepared for the realities of the workshop.

How VR Transforms Hazard Training

Furnace Safety Simulations: VR replicates high-heat environments, allowing staff to practise procedures without risk.

Chemical Handling Modules: Workers learn safe handling of polishing and finishing agents digitally.

AI Avatars: Intelligent supervisors monitor practice sessions and provide corrective feedback.

Preserving Craftsmanship Through Compliance

By digitising SOP training, glassmakers can pass down artisanal skills while ensuring safety and compliance are built into every process. This balance protects both heritage and workforce wellbeing.

Business Benefits

Workforce Protection: Reduces accidents in high-risk environments.

Audit Confidence: Digital evidence of SOP adherence simplifies inspections.

Heritage Protection: Ensures artisanal skills are preserved in a safe, modern framework.

Why Spark Emerging Technologies?

Spark delivers VR hazard simulations and AI-driven compliance systems tailored for industries like luxury glassmaking. Our expertise ensures heritage craft is preserved while meeting the demands of modern legislation.

Call to Action

Could your glassmaking facilities benefit from immersive hazard awareness training? Partner with Spark Emerging Technologies to embed compliance, safety, and artistry into your production process.

© 2026 All Rights Reserved | Company Reg No. 05327622 | Spark Emerging Technologies Limited