Reducing Downtime in Precision Instrument Manufacturing with Digital Twins

Author: Spark Team

Author: Spark Team

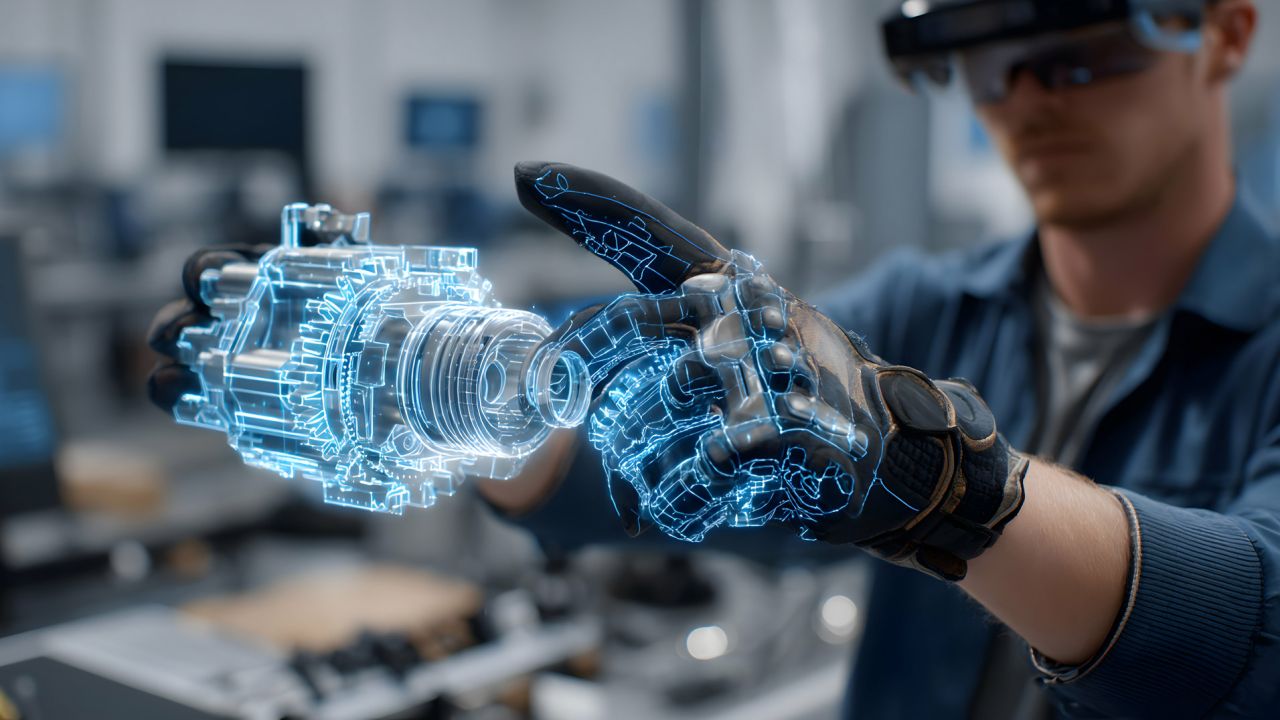

Reducing Downtime in Precision Instrument Manufacturing with Digital Twins

Precision instruments — from luxury watches to scientific equipment — demand flawless accuracy. Even the smallest deviation can compromise functionality, safety, and reputation. With regulators enforcing strict SOP and HSE requirements, manufacturers must modernise training and maintenance systems to protect both workers and product integrity.

Legislation Raising Standards

Regulatory frameworks such as ISO 9001 for quality management and ISO 13485 for medical devices place strict obligations on process control. Companies must demonstrate that every SOP is consistently followed, and that equipment is maintained to exacting standards.

The Downtime Dilemma

Traditional maintenance and training methods often require halting live production lines, leading to costly downtime. For manufacturers producing premium instruments, this loss of productivity directly impacts profitability and client satisfaction.

How Digital Twins Provide Solutions

Virtual Maintenance: Staff practise complex procedures on digital twins of equipment, reducing reliance on live systems.

SOP Testing: New processes can be trialled virtually before implementation.

AI Oversight: Avatars monitor digital training, ensuring procedures are performed correctly.

Consistency Across Global Sites

Digital twins allow global facilities to standardise procedures and training. This ensures that whether instruments are manufactured in Europe or Asia, SOPs are followed identically, protecting brand reputation worldwide.

Business Benefits

Reduced Downtime: Training on digital twins means live production remains uninterrupted.

Compliance Assurance: Virtual training logs provide audit-ready records.

Quality Protection: Instruments consistently meet luxury and regulatory standards.

Why Spark Emerging Technologies?

Spark creates high-fidelity CGI and digital twins integrated with AI-driven compliance tracking. We help manufacturers reduce downtime, maintain SOP adherence, and safeguard product quality in highly regulated markets.

Call to Action

Is your precision instrument facility ready to embrace digital twin technology? Contact Spark Emerging Technologies today to reduce downtime, protect compliance, and ensure flawless accuracy in your manufacturing process.

© 2026 All Rights Reserved | Company Reg No. 05327622 | Spark Emerging Technologies Limited